Around the beginning of the year, my friend Christine reached out and asked if I was interested in teaming up with her to make a small shoe brand. My initial thought was, “Na, I have way too much on my plate as it is.” But, its one of those ideas that kind of takes root and wont let go. Before long, I found myself in Leon, Mexico, the shoemaking capital of the western hemisphere.

Mexico produces about 250 million pairs of shoes annually, and about 70% of those are produced in Leon. It has a rich history of footwear manufacturing, and an entire ecosystem built around it with tanneries and suppliers for everything you can think of relating to shoes. It’s also conveniently close. We had initially reached out to Italian manufacturers, but weren’t given the time of day. Mexico was a similar story while reaching out to the Footwear Chamber of Commerce in Leon, however after doing some research and sending out a ton of emails, we made a few contacts and decided to visit.

One of the first places we visited was a last factory called Hormas. Its a state of the art facility, and a partner to Formifico Romagnolo in Italy. We were given a tour, shown where the modellers first make the last by hand, where it gets 3D scanned, and the machines that cut out the lasts from blanks made on site. They also have a processing facility where they repurpose the plastic shavings back into last blanks.

I was immediately impressed by the modeller’s skill and experience. I brought a last that I wanted to to get scanned there. The modeller took a little bit of time examining it, then immediately told me that it was too short and should be extended a couple millimeters in the toe. The assessment was spot on. I had just made a pair of boots on that last, and was wearing them for the first time. When I first put them on, the fit felt perfect, but after walking for a while, your feet swell a bit and they were pinching my small toe. A few millimeters there would be perfect to alleviate it. I ended up getting two other lasts designed there, a “service boot” style last, and a ladies last.

Here is their last library. You can select whichever style you like, and they’ll make whatever modifications you want to it, all for only $180 (which includes a last).

Last blanks, ready to be CNC’ed

The machine that cuts out the lasts, pretty neat how precise and high tech it is

They recycle all of their plastic material here, molding it back into last blanks

Assembly line where the guys put all the heel plates on and make the hinges

Next was a visit to a small tannery in town. They receive “blue” skins already de-haired and chrome tanned from another tannery out of town. Here they do all of the post processing, infusing the leather with fats, oils, and waxes, then doing the finishing. This particular tannery had really nice lining leathers that customers such as Tecovas and Thursday Boots use.

Some good boys keeping an eye out.

“Blue” chrome tanned skins received, ready for tanning

Drums where they infuse the leather with fats, oils, etc.

Drying skins

We also went on a tour of Hormas El Arbol, another last factory.

Here is the station where they recycle old, used, lasts.

Machine that molds new last blanks, its huge.

Cutting out the last hinges

Making adjustments to the last with a sander. He had cutouts that he lined the last up with, to make sure it was the right shape.

Where they manufacture heel plates

We also toured WYNY, one of the largest tanneries in Mexico. They specialize in veg tanning. I should note, we reached out to them before this trip to arrange a tour. Their head of international sales came out and picked us up from by our AirBnB, then gave us a full tour of the factory, and took us to our next destination. We were just blown away at the service.

Here are pallets of salted hides before they’re tanned.

I should mention, the smell in this area is intense. Not for the faint of heart or stomach. Its like a mixture of a bit of rot, with a strong chemical aftertaste.

Drums with raw hides, mixed with lime to de-hair and prep for tanning.

De-haired hides

Tanning pits, the hides are mixed with bark from chestnut, mimosa, or quebracho trees. They sit in the pits for about a month and absorb the tannins from the bark. While you can’t say all veg tan leather is better than chrome tanned, there are certain advantages to veg tanning. Veg tanned leather has some antimicrobial properties, and when it eventually decomposes, it doesn’t leave chrome salts behind. That being said, there are fantastic leathers in both veg and chrome tan, or mixtures of the two. One drawback from a business point of view, is that it takes about a month to do veg tan, while chrome tanning takes a few days.

Tanning bark, very finely ground. It left my hand feeling weirdly tacky.

The machine applies a finish to the leather, workers brush it to keep dust and grime from being infused with the finish

Machine compressing some sole leather

Temperature controlled drying room

Spray nozzles that apply dye to the leather

Out of the machine, they’re surprisingly hot on their way out

Here is the best damn lining leather I have ever handled in my life. Veg tanned, incredibly soft and supple. Like, you won’t believe how good it feels unless you actually handle it in person, its that good. Apparently veg tanned skins have anti-microbial properties too, according to the guys at the tannery.

One of the manufacturers we visited

We also went to Cuadra, which is a huge operation. They make Corral Boots (their house brand), and make shoes and boots for various other brands, including Tecovas. They have their own exotics tannery, shoe manufacturing facility, and a HUGE warehouse full of exotic skins at this site.

The big python skin was a man eater, notice the morbid picture on it…

Just boxes and boxes and boxes of gator, ostrich, stingray, kudu, lizards, snakes, elephant, etc. I can’t even begin to guess at the dollar value of the skins there.

At the tannery, gator hides being dyed and finished

Python skin covered bike? Nice

Lab where they mix colors, and there is a guy glazing gator skins in the back, unfortunately I didn’t take any pics, just videos. Its a cool process, there’s a large arm with a glass ball on the end that goes over the skin. The friction causes the glazing effect. That’s the extremely simplified version anyway!

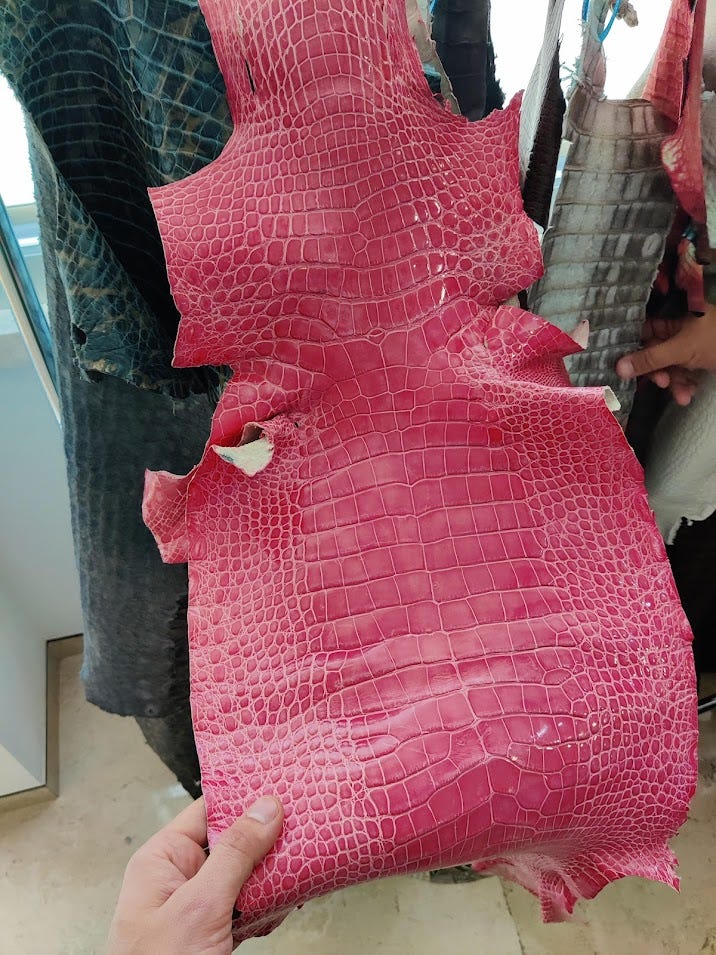

I *really* want to make a pair of ladies Chelsea boots out of this pink gator. You can also catch a glimpse of Himalayan Alligator behind the pink (white and gray skin to the right). Google it if you’re curious what a quarter million dollar Hermes bag looks like. They tan the skins at this facility, and according to Fernando, the owner, they had made a mistake in the original tannage, Hermes rolled with it and a star was born.

And here is their boot manufacturing facility, I didn’t take very many pictures because its a huge operation, very industrial.

We also visited an elastics factory, but they didn’t want us taking pictures of all the machines and their processes, so check out some of the cool stuff they make instead.

One of the lasts I ordered finally ready from the modeller, those dudes are quick! They modeled all three lasts we ordered in a week.

And here is Christine with the ladies last we got designed.

I didn’t include pictures, but we also visited a box factory (and got the whole process tour), a shoelace factory, and a sole factory. The sole factory was very impressive, they’re a world class facility that used to partner with Vibram, and export all over the world. Incidentally, the Dainite clone that Thursday Boot uses is made at that factory. One of the more interesting things we saw there was a special rubber formulation they make that is made to break down over 50 years. Nice to know you can use something that wont end up hanging out in a landfill for a few hundred years.

All in all, I was very impressed with Leon. The people were all wonderful and hospitable. We’re just a couple of thirty somethings without a whole lot of cash to throw around, but everywhere we went people took the time to show their factories and tell us all about their processes. Glad to visit, and I plan to be back as soon as I can!

Next stage is getting a bunch of samples made to the quality that a shoe nerd like myself would be happy to wear!